OSHA

OSHA

Tags

Animal Care (4)

Biosafety (228)

Biotech (1)

Bloodborne Pathogens (1)

Burn Awareness Week (1)

Business Performance (4)

Chemical Safety (224)

Corona Virus (9)

COVID-19 (14)

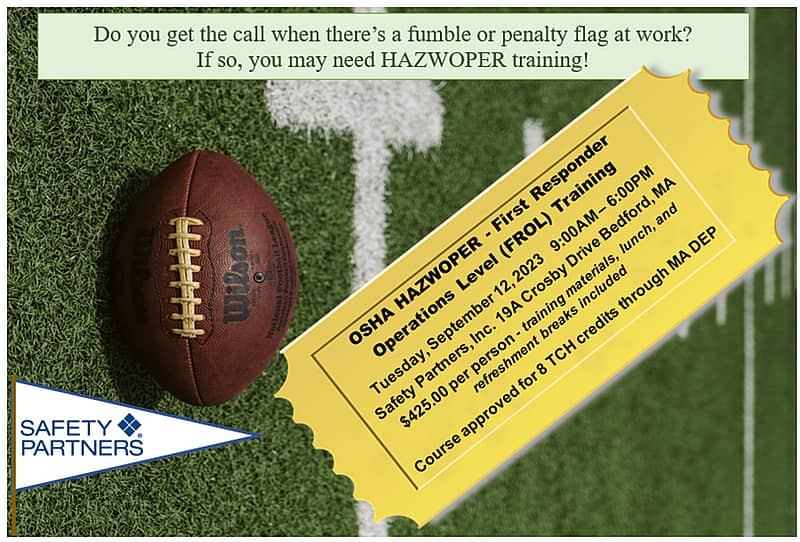

DEP (6)

Disinfectants (1)

DOT (4)

Earth Day (2)

EHS (10)

en (2)

Environmental Health & Safety (EHS) (401)

EPA (7)

Fall Protection (5)

FPW (2)

Hazardous (2)

Hydrofluoric Acid Safety (1)

Hygiene (7)

IH (7)

Incidents Accidents and Near Misses (21)

Industrial Hygiene (7)

International Women's Day (1)

Lab Relocation and Decommissioning (5)

Lab Safety (10)

labsafety (9)

Life Science (2)

NFPA (8)

NYC (4)

Office Safety Culture (193)

OSHA (179)

Permits and Licenses (17)

Poison Prevention (1)

Radiation Safety (128)

Regulatory Compliance (322)

Safety (11)

Safety Tips (447)

Training Contact Hours (TCH) (12)

Waste Water (7)

Women in Science (1)

Workers' Memorial Day (1)

Workplace Injuries (8)