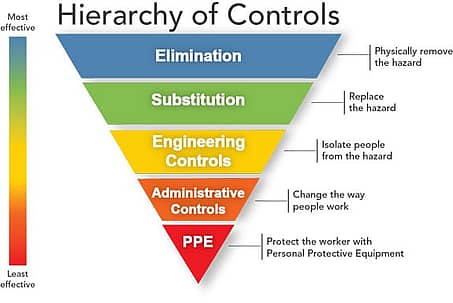

A basic tenant of any good industrial hygiene program is the application of the hierarchy of controls. This mantra dictates that identified hazards should be addressed in the following order:

A basic tenant of any good industrial hygiene program is the application of the hierarchy of controls. This mantra dictates that identified hazards should be addressed in the following order:

- removal of hazard

- substitution of hazard

- engineering controls

- administrative controls

- personal protective equipment (PPE)

Generally speaking, the first two options are not available by the time it reaches the safety team. This means that we are usually charged with finding the appropriate control mix to ensure employees are adequately protected. This typically takes the form of some combination of engineering, administrative and PPE controls.

Engineering controls include equipment that physically removes or isolates a hazard from the employee. Examples of engineering controls include fume hoods, interlocks on equipment and separate control rooms. The proper use of an appropriate engineering control will either remove or greatly reduce the possibility of hazard exposure. As the most robust form of hazard control, engineering options are always the first to be explored, and should be instituted whenever feasible.

The second tier involves the use of administrative controls. These controls protect the employee through the use of knowledge-based action items, such as training, SOPs and signage. This level of control can be very helpful, especially when used in tandem with engineering controls. The importance of ensuring all employees are aware of possible hazards and are given the information they need to protect themselves is reflected in this level of control.

The last resort is the use of PPE. This type of control does not remove the hazard from the work environment, and is reliant on proper use by the wearer. Because of this, PPE is not considered a very robust control and should only be used as a last resort, or as a precaution in case of failure of another level of control. Some examples of PPE include lab coats, respirators and gloves.

When evaluating a hazard in the workplace, always keep the hierarchy of controls in mind. When implemented according to this priority, the best possible controls for each hazard can be implemented resulting in greater employee protection.

This is the second blog in a ten-part Industrial Hygiene blog series that we are featuring monthly. In December we posted the first IH blog “What is Industrial Hygiene?”. We welcome your input on series! To provide feedback, or for questions about industrial hygiene and for information on how input from a Certified Industrial Hygienist can benefit your safety program, please email [email protected].

Image Source: NIOSH